Design and Build of the El Salitre Wastewater Treatment Plant, Phase II, in Colombia

AKTOR, as the leader of the CEPS consortium (Consorcio Expansión PTAR Salitre), undertook the design and build project of Phase II of the El Salitre Wastewater Treatment Plant

Design and Build of the El Salitre Wastewater Treatment Plant, Phase II, in Colombia

AKTOR, as the leader of the CEPS consortium (Consorcio Expansión PTAR Salitre), undertook the design and build project of Phase II of the El Salitre Wastewater Treatment Plant

Project Information

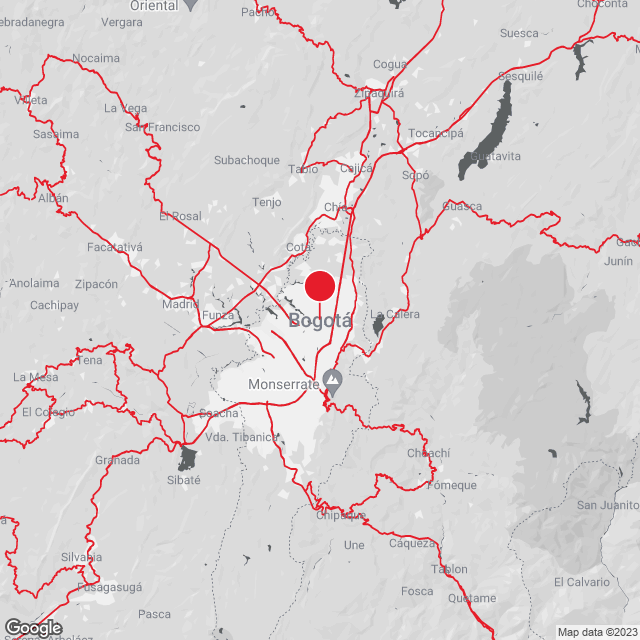

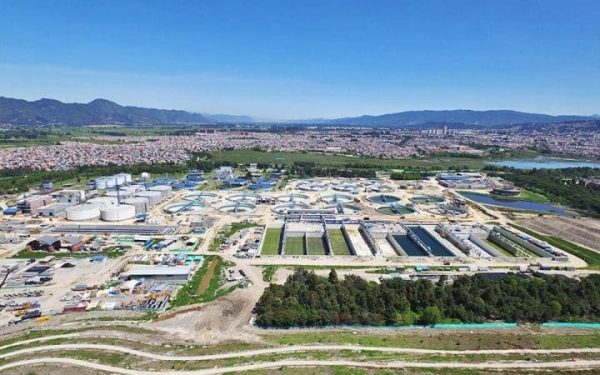

AKTOR, as the leader of the CEPS consortium (Consorcio Expansión PTAR Salitre), undertook the design and build project of Phase II of the El Salitre Wastewater Treatment Plant, in Bogotá, capital of Colombia.

This project, contracted by the Regional Autonomous Corporation of Cundinamarca (CAR), is part of a major project for the decontamination and recovery of the Bogotá River, which is vital for the environmental recovery of the wider region.

The El Salitre Wastewater Treatment Plant will have a capacity of 7 m3/s (approximately 600,000 cubic meters per day), preventing a significant quantity of polluting load from reaching the river.

In particular, the project includes the detailed design, construction of the works, supply and installation of equipment, commissioning and assisted operation of the expansion and optimization of the El Salitre Wastewater Treatment Plant.

The current facilities of the El Salitre Wastewater Treatment Plant, Phase I, were commissioned in 2000 and can process 4 m3/s of wastewater (approximately 350,000 cubic meters per day), up to the level of primary treatment. Current conditions and future planning require the capacity of the facilities to be increased and the treatment process to be enhanced, so that the entire wastewater flow can be treated biologically.

In Phase II, the capacity for full treatment is increased up to 7 m3/s, while the pretreatment and primary treatment units are able to receive and process up to 14 m3/s.

The pre-treatment process involves the removal of bulky and solid waste, as well as grit and grease, while protecting the downstream wastewater treatment units. In primary sedimentation tanks, with a diameter of 45 m, part of the solid particles settles and is removed along with the primary sludge, while floating materials are also collected and removed.

In the biological reactors, organic materials and nutrients are broken down and metabolized by aerobic microorganisms, through aeration. In secondary sedimentation tanks, with a diameter of 55 m, microorganisms and other suspended particles are separated from treated wastewater, resulting in the production of secondary sludge and treated water.

The sludge produced through the clarification process is pumped to anaerobic digesters, where the sludge is stabilized, so that the final product, after additional treatment, can be used as fertilizer. The biogas produced during the anaerobic digestion process is used in cogeneration units, for the production of electricity and thermal energy.

When the above processes are completed, the treated effluent goes through the disinfection process. The final product, free of organic material and bacteria, is then discharged into the Bogotá River, enabling its recovery to a living ecosystem.