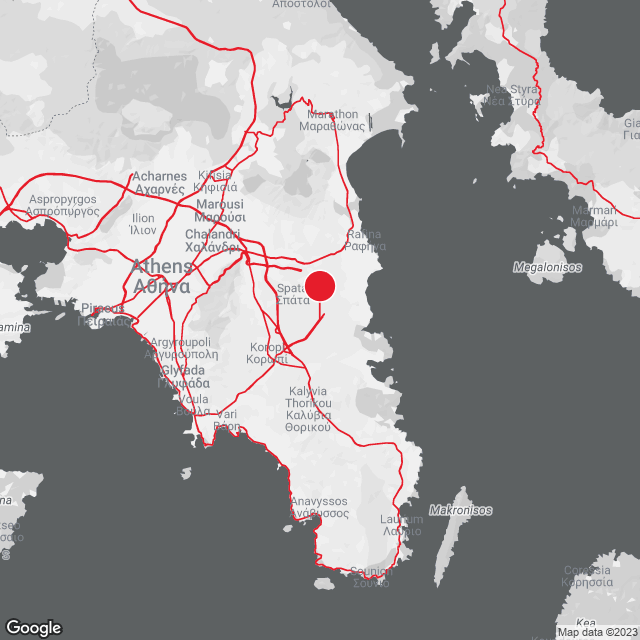

Provision of Maintenance Services to the Baggage Handling System of the Athens International Airport “Eleftherios Venizelos”

AKTOR FM is responsible for the maintenance of the Baggage Handling System (BHS) of the Athens International Airport (AIA) “Eleftherios Venizelos”.

Provision of Maintenance Services to the Baggage Handling System of the Athens International Airport “Eleftherios Venizelos”

AKTOR FM is responsible for the maintenance of the Baggage Handling System (BHS) of the Athens International Airport (AIA) “Eleftherios Venizelos”.

Project Information

Confirming its leading expertise in the delivery of innovative solutions to airport facilities, AKTOR FM is responsible for the maintenance of the Baggage Handling System (BHS) of the Athens International Airport (AIA) “Eleftherios Venizelos”.

More specifically, AKTOR FM provides Preventive, Reactive, Corrective and Predictive Maintenance Services to the BHS of AIA, while also undertaking projects for its upgrade.

The BHS of the AIA consists of two fully independent automated baggage halls that include:

- 2 tilt tray sorters (1 per hall) with 200 trays per sorting system, with a speed of 1.9 m/sec and a sorting capability of 4,675 baggage/hour per system

- 144 ticket-control points (Check in) with a capacity of 4,320 baggage/hour per hall

- Hold-Baggage-Inline-Screening-System with 4 screening lines per hall, capable of handling 4,620 baggage/hour

- 11 Reclaim Baggage Loops

- 2 Transfer Lines per hall with a capacity of 122 baggage/hour per line transfer

- 5 Early bag Conveyor Lines of 283 m total length per hall and a storage capacity of 331 bags per hall

- 2 Manual Encoding Stations (MES) per Hall with a capacity of 360 baggage/hour per MES

- 1 conveyor line per hall (intersorter) for interconnection of the 2 Baggage halls, with a capacity of 181 baggage/hour per hall Intersorter:

- 1 Out of Gauge line per hall for oversize – overweight baggage

- Level 3: 230 bags/hour per hall

Within the framework of offering “Turnkey Products” construction services, AKTOR FM also implemented the project of upgrading of the Programming Logic Controller (PLC) of the Oil Separator Pumps installation of AIA. Finally, the company undertook the project of painting the air ducts of the halls using special personnel for work at height.